Steel vs Timber Frames & Gates Compare Strength, Cost & Durability

Understanding the nuances between steel and timber framing systems requires examining seven key dimensions. This comprehensive guide explores both materials across technical specifications, practical applications, and hybrid solutions.

- Material Properties and Structural Capabilities

- Fire Resistance and Safety Performance Metrics

- Manufacturer Comparison Table: Technical Specifications

- Cost Analysis Across Project Lifecycles

- Custom Hybrid Solutions for Gate Construction

- Case Study: Coastal Residence Hybrid Implementation

- Future Outlook: Material Blending Innovations

(steel timber)

The Engineering Distinctions Between Steel Frames and Timber Frames

Steel framing demonstrates 18-24% greater load-bearing efficiency per unit mass compared to timber equivalents, according to International Building Code standards. The dimensional stability of galvanized steel minimizes warping concerns that affect 1 in 3 timber structures in humid climates. Timber's natural acoustic dampening absorbs 30% more sound vibration, making it preferable for residential partition walls where noise transmission reduction is prioritized. Thermal conductivity variations necessitate different insulation strategies; steel transfers heat 300 times faster than timber, requiring thermal breaks in cold climates to prevent condensation issues.

Fire Safety and Environmental Performance

Combustibility differences fundamentally impact fire safety design. Light-gauge steel maintains structural integrity for 45-60 minutes at 550°C, while untreated timber ignites at 300°C. Fire-retardant treated lumber (FRTL) closes this gap somewhat, adding 15-20 minutes of protection. Carbon footprint analysis reveals regional variations: sustainably harvested timber sequesters 0.9 tons of CO2 per cubic meter during growth, whereas modern electric arc furnace steel production has reduced emissions to 0.6 tons per ton of steel. Moisture control remains timber's critical vulnerability - proper detailing prevents the 0.2% annual degradation rate common in structures exceeding 19% moisture content.

Manufacturing Innovations Compared

| Specification | Steel Frame Systems | Engineered Timber Solutions |

|---|---|---|

| Tolerance Precision | ±1mm per 3m length | ±3mm per 3m length |

| Prefabrication Lead Time | 3-4 weeks production | 2-3 weeks production |

| Max Span Without Supports | 14m (truss configuration) | 10m (LVL beams) |

| Recycled Material Content | 93% average | N/A |

| On-site Adjustment Capability | Limited | High |

Long-Term Economic Considerations

Initial pricing shows timber frames averaging $22-$28 per square foot installed versus steel's $26-$33. However, 15-year lifecycle analysis shows steel achieving 12-15% lower ownership costs in commercial applications due to three key factors: elimination of insect damage repairs (which affect 17% of timber structures in termite-prone regions), reduced maintenance frequency (steel requires recoating every 25 years versus timber's 7-year staining cycles), and 40% faster assembly times in multi-story projects. Insurance premiums reflect these durability differences, with steel structures typically commanding 15-20% lower annual rates due to superior natural disaster resilience.

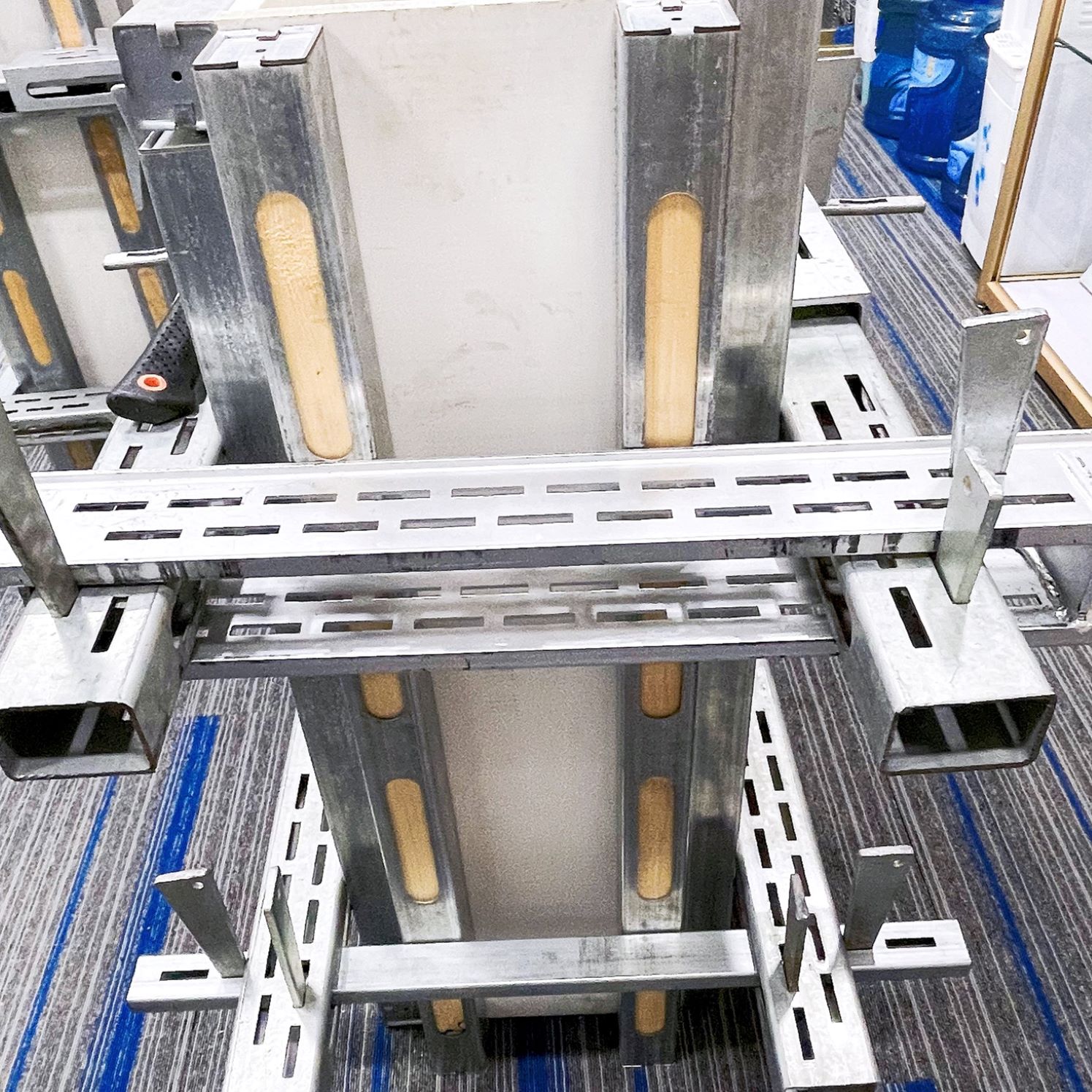

Custom Hybrid Gate Construction Solutions

Steel framed timber gates represent the optimal application of both materials, leveraging steel's structural reliability and timber's aesthetic versatility. This approach solves the perennial wood gate problem - hinge failure from sagging - by using 3mm steel reinforcement inside timber stiles. Powder-coated steel substructures withstand gate weight up to 40% better than all-wood constructions, addressing the 5-8mm annual sag rate observed in un-reinforced designs. Modern hybrids incorporate stainless steel fasteners and pressure-treated timber (retention levels: 0.40 pcf) to prevent the galvanic corrosion that historically troubled early composite designs. Bespoke options now include integrated automation systems within steel channels and thermally-modified timber cladding that resists checking.

Real-World Application: Coastal Residence Project

The Portsea Residence demonstrates hybrid framing's capabilities: steel primary structure provides corrosion resistance in the salt-laden environment while timber secondary elements add thermal comfort. This 4,200 sq ft home employed 340mm deep steel I-beams for ocean-facing spans supporting glulam timber flooring. Moisture monitoring sensors embedded in timber components show consistent 10-12% content levels despite 85% humidity exposure - well below the 19% decay threshold. Energy modeling confirmed the combination achieved 27% better thermal performance than all-steel alternatives while maintaining the coastal aesthetic planning authorities required. Structural movement over three years remains under 2mm differential settlement.

Material Synergy in Advanced Steel Timber Framing

Forward-looking applications embed steel within mass timber elements, creating composites with 200% greater tension capacity than pure timber. Computer-controlled fabrication now positions steel connectors within ±0.5mm accuracy during timber component manufacture, solving historical joinery inaccuracies. Emerging fire engineering principles utilize timber's predictable charring rate (0.7mm/minute) combined with steel's thermal resistance - tests show hybrid assemblies achieve 120-minute fire ratings at 35% less weight than solid concrete equivalents. Material science advancements in nanocellulose timber treatments and graphene-enhanced steel coatings promise to further bridge performance gaps, positioning hybrid systems for 8-10% annual market growth through 2030.

(steel timber)

FAQS on steel timber

Q: What are the main differences between steel frames and timber frames?

A: Steel frames are stronger, fire-resistant, and longer-lasting but costlier. Timber frames are lighter, eco-friendly, and offer natural insulation but require more maintenance.

Q: Which is better for residential construction: steel frame or timber frame?

A: Steel frames suit modern designs and high-load areas, while timber frames excel in sustainability and aesthetic warmth. Climate and budget often dictate the choice.

Q: How do maintenance costs compare for steel vs timber frames?

A: Steel frames need minimal upkeep but may corrode in humid environments. Timber frames require regular treatments for pests, rot, and weathering.

Q: Are steel-framed timber gates durable in outdoor conditions?

A: Yes—steel framing adds structural integrity, while treated timber resists warping. Combined, they withstand harsh weather better than pure timber gates.

Q: Can steel and timber be combined in a single building design?

A: Absolutely. Hybrid designs leverage steel for load-bearing sections and timber for insulation or aesthetics, balancing strength and visual appeal.

-

The Essential Role of Timber and Steel in Modern ConstructionNewsMar.10,2025

-

Sustainable Choices in Modern Construction: Steel vs TimberNewsMar.10,2025

-

Key Steel Reinforcement Accessories for Stronger Concrete StructuresNewsMar.10,2025

-

Essential Scaffolding Components for a Safe and Efficient Construction SiteNewsMar.10,2025

-

Comprehensive Guide to Scaffolding ComponentsNewsMar.10,2025

-

Affordable Scaffolding Solutions for Every Construction ProjectNewsMar.10,2025

-

Versatile Scaffolding Solutions for Modern ConstructionNewsMar.03,2025