1 月 . 13, 2025 13:17

Back to list

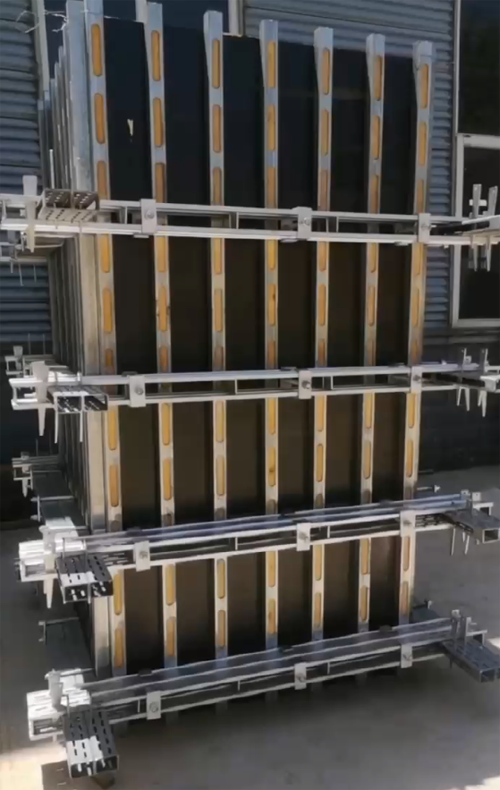

wall reinforcement

Wall formwork systems are integral components in the construction industry, acting as temporary or permanent molds into which concrete is poured to shape and build walls. These systems come with distinct advantages that make them indispensable for modern construction, driving increased efficiency, safety, and precision.

Education and training in using wall formwork systems play a crucial role in their effective deployment. Builders and contractors who undergo specialized training are better equipped to handle the complexities of these systems, translating into fewer errors and reduced construction costs. Certifications from recognized institutions add a layer of credibility, ensuring clients that industry professionals are both knowledgeable and skilled. In terms of authoritativeness, industry leaders often collaborate with academic institutions to research and develop innovative formwork solutions. These collaborations further the understanding of material performance, load-bearing capacities, and adaptive design features that cater to diverse construction needs. Publications and case studies from such collaborations serve as invaluable resources for professionals seeking to enhance their expertise. To build trust with potential clients, companies offering wall formwork solutions often provide warranties and demonstrate their product's capabilities through successful project case studies. Reviews and testimonials from previous projects offer insight into product performance and customer satisfaction, serving as evidence of the system’s reliability and efficacy. In conclusion, wall formwork systems represent a confluence of innovation, precision, and practicality in construction. By investing in the right expertise and technologies, construction projects can benefit from faster completion times, enhanced safety, and superior quality, thus cementing their role in shaping our built environment’s future.

Education and training in using wall formwork systems play a crucial role in their effective deployment. Builders and contractors who undergo specialized training are better equipped to handle the complexities of these systems, translating into fewer errors and reduced construction costs. Certifications from recognized institutions add a layer of credibility, ensuring clients that industry professionals are both knowledgeable and skilled. In terms of authoritativeness, industry leaders often collaborate with academic institutions to research and develop innovative formwork solutions. These collaborations further the understanding of material performance, load-bearing capacities, and adaptive design features that cater to diverse construction needs. Publications and case studies from such collaborations serve as invaluable resources for professionals seeking to enhance their expertise. To build trust with potential clients, companies offering wall formwork solutions often provide warranties and demonstrate their product's capabilities through successful project case studies. Reviews and testimonials from previous projects offer insight into product performance and customer satisfaction, serving as evidence of the system’s reliability and efficacy. In conclusion, wall formwork systems represent a confluence of innovation, precision, and practicality in construction. By investing in the right expertise and technologies, construction projects can benefit from faster completion times, enhanced safety, and superior quality, thus cementing their role in shaping our built environment’s future.

Share

Next:

Latest news

-

The Essential Role of Timber and Steel in Modern ConstructionNewsMar.10,2025

-

Sustainable Choices in Modern Construction: Steel vs TimberNewsMar.10,2025

-

Key Steel Reinforcement Accessories for Stronger Concrete StructuresNewsMar.10,2025

-

Essential Scaffolding Components for a Safe and Efficient Construction SiteNewsMar.10,2025

-

Comprehensive Guide to Scaffolding ComponentsNewsMar.10,2025

-

Affordable Scaffolding Solutions for Every Construction ProjectNewsMar.10,2025

-

Versatile Scaffolding Solutions for Modern ConstructionNewsMar.03,2025

Related Products