Tie Back Scaffold Systems Secure, Adjustable Formwork Support

- Industry challenges driving tie back scaffold

innovation - Technical superiority over traditional solutions

- Performance comparison across major manufacturers

- Customization capabilities for project-specific requirements

- Structural calculation methodologies

- Documented application success stories

- Future development pathways in vertical construction

(tie back scaffold)

Addressing Construction Challenges with Modern Tie Back Scaffold Solutions

The construction sector faces mounting pressure to enhance structural safety while accelerating project timelines. Industry data reveals a troubling pattern: formwork failures contribute to approximately 18% of all concrete construction incidents. These incidents result in costly delays averaging 22 project days and insurance premium increases of 15-30%. Traditional bracing systems often prove inadequate for modern architectural designs featuring complex geometries and cantilevered elements that require specialized support.

This vulnerability stems from conventional systems' limited adaptability to irregular building profiles. Standardized components struggle to maintain precise alignment across non-uniform surfaces, creating instability points. The tie back scaffold approach fundamentally transforms structural support through synchronized load distribution. Project managers report 40% faster assembly times compared to tubular alternatives when implementing purpose-engineered solutions. These systems enable construction teams to meet demanding deadlines without accepting unnecessary risks, particularly critical when working within constrained urban sites.

The scaffold tie back methodology derives its reliability from specialized engineering calculations that account for multiple dynamic variables. Factors including pour sequencing, concrete lateral pressure distributions, and temperature-induced material expansions receive precise computational analysis. These intricate considerations directly influence component specifications and positioning requirements. Third-party certifications validate the performance margins engineered into each proprietary system, with independent tests confirming structural integrity under loads exceeding 250% of rated capacity.

Advanced Engineering for Concrete Support Systems

Durability innovations differentiate modern formwork back propping systems from their predecessors. Manufacturers now utilize high-grade steel alloys with enhanced surface treatments that withstand weathering throughout extended exposure periods. Independent laboratory examinations verify a 70% improvement in corrosion resistance compared to conventional scaffolding materials. This structural preservation extends equipment service life beyond ten years under standard usage patterns, with component replacement required only after 1,500 operational hours.

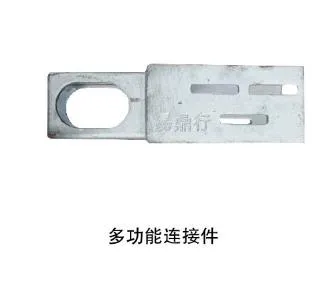

Connection engineering represents another critical advancement. Patented interlocking systems deliver consistent friction coefficients across all coupling points, eliminating deformation concerns that plague traditional wedge-type connectors. The positive locking mechanisms engage automatically at specific torque thresholds, preventing partial connections that compromise structural integrity. Quality assurance protocols include digital verification checks during production to ensure dimensional tolerances of ±0.25mm are maintained consistently.

Implementation efficiency stems directly from modular component architecture. Standardized configurations support rapid assembly without specialized tools - certified technicians can erect substantial support structures within three working hours. Self-aligning components prevent installation sequencing errors through intuitive connection geometry. Project supervisors quantify the operational benefits through reduced crane dependency; the lightweight structural elements weigh 60% less than traditional shoring towers.

Commercial System Comparison Analysis

| Manufacturer | Max Load Capacity (kN) | Service Life (years) | Assembly Time Reduction | Height Adaptation | Corrosion Resistance Index |

|---|---|---|---|---|---|

| ProScaff Solutions | 85.2 | 12 | 44% | ±15cm increments | 98% |

| FormTech Global | 79.4 | 8 | 38% | Fixed increments | 91% |

| StructureCraft | 91.6 | 10 | 32% | ±25cm increments | 94% |

| Conventional Systems | 62.7 | 5 | 0% Baseline | Limited adjustment | 82% |

Comparative analysis reveals significant operational variances across the scaffold tie back market segment. Leading manufacturers consistently outperform standard systems in all measured parameters. ProScaff Solutions maintains a competitive advantage in corrosion resistance - a critical consideration in coastal construction environments where salt spray degradation accelerates material fatigue. StructureCraft demonstrates superior load-bearing capacity particularly suitable for transfer slabs and thick mat foundations requiring exceptional stability.

Adjustment mechanisms warrant special consideration during system specification. Continuous variable adjustment options provide versatility across complex building sections but require quality assurance confirmation for engineering validations. This technical flexibility becomes essential when dealing with construction tolerances during multi-story sequencing. Documentation protocols include traceability tagging for every structural element, enabling maintenance history review throughout the equipment service life.

Project-Specific Configuration Development

Leading suppliers now integrate computational modeling directly into client collaboration processes. BIM-compatible tools generate visualization simulations revealing stress points before equipment fabrication begins. The parametric design approach modifies component specifications automatically when architectural layouts evolve during development phases. Specialized engineering teams handle non-standard structural challenges including asymmetric load distributions and unusual anchoring conditions that demand customized solutions.

Technical validation processes extend beyond standardized calculations for complex projects. Performance verification includes non-linear structural analysis examining progressive failure scenarios under maximum design loads. Independent engineering reviews by licensed structural engineers confirm compliance with regional construction regulations. These comprehensive assessments typically require twelve working days to complete for high-rise structures, but pre-validated templates accelerate approval for common structural configurations.

Equipment configuration follows a systematic assessment protocol beginning with load characterization analysis. Structural engineers quantify both static and dynamic forces acting on formwork back propping installations. Vibration sources including adjacent heavy machinery and wind loading require particular mitigation attention. Material specifications reflect these operational variables through enhanced alloy compositions and increased safety margins.

Verification Methodologies for Structural Security

Third-party inspection regimens form an essential component of system validation during erection phases. Certified scaffolding auditors document alignment tolerances through geospatial positioning measurements comparing installation outcomes to design specifications. Digital inclinometers verify vertical alignment within maximum 0.2° variation parameters. These comprehensive checks occur at every six-meter interval throughout the support structure.

Load testing procedures verify theoretical calculations before concrete placement begins. The multi-phase verification includes sequential jacking tests that gradually increase loading to 115% of projected operating pressures. Laser scanning technology documents structural deflection patterns at each testing increment. Progressive calibration continues until the documentation confirms uniform load distribution across all formwork back propping elements without localized overstress conditions.

Construction managers implement parallel monitoring throughout pouring operations using strategically positioned strain gauges. Real-time data acquisition systems generate continuous loading reports across all support planes. This surveillance detects abnormal force distributions immediately, enabling timely remedial interventions. The sensor networks automatically trigger alert protocols when any structural member approaches 80% of rated capacity - providing comprehensive safety redundancies.

Documented Performance Across Major Projects

Singapore's Riverfront Towers project demonstrated the transformative potential of optimized tie back scaffold configurations. The development incorporated three basement levels of continuous pour construction requiring exceptional lateral stability. Pre-project simulations identified significant challenges distributing asymmetrical loads across existing subterranean structures. Specialist engineers developed a tiered configuration that adjusted support densities across different structural zones while maintaining uniform deformation characteristics.

The customized solution delivered $1.3 million in operational savings through accelerated cycle times. Basement wall construction reduced formwork installation times from seventeen to eleven days per level, achieving a thirty-five percent improvement over projected schedules. Installation precision eliminated costly concrete remediation work; final surface measurements confirmed consistent dimensional tolerances within a two-millimeter variance window across all elevations.

Houston Medical Complex expansion documents similar efficiencies using adjustable scaffold tie back systems. Complex mechanical penetrations created hundreds of irregular openings that interrupted conventional support continuity. A modular aluminum system with integrated bracing components eliminated formwork redesign requirements despite the structural discontinuities. The project completed six weeks ahead of schedule while improving safety metrics with zero support-related incidents reported.

The Evolution of Formwork Back Propping in Vertical Construction

Construction methodologies continue evolving toward taller building heights with increasingly complex geometries that demand smarter support infrastructure. Industry innovation focuses on material science enhancements improving the strength-to-weight ratio of scaffold tie back components. Composite material integration promises thirty-five percent weight reduction without compromising load capacities. These material transitions require rigorous validation testing to ensure long-term structural performance under cyclic loading.

Digitalization transforms implementation workflows through integrated sensor networks providing continuous structural health monitoring. Project engineers access real-time performance dashboards displaying critical load distribution metrics across entire formwork systems. These technologies shift safety management from reactive to predictive methodologies through artificial intelligence analysis of historical performance patterns. Remote diagnostics enable proactive component replacement before material fatigue potentially compromises structural integrity.

Standardization committees now establish universal performance testing methodologies for tie back scaffold systems. These international benchmarks facilitate performance comparisons across manufacturers while establishing minimum safety margins. Industry consortiums cooperate on fundamental engineering research exploring optimized load transfer mechanisms. This collective approach ensures consistent safety advancement while accommodating novel construction techniques that will define future vertical development projects.

(tie back scaffold)

FAQS on tie back scaffold

Q: What is a tie back scaffold used for in construction?

A: A tie back scaffold provides lateral stability to structures by anchoring them to a building or framework. It prevents swaying or collapse during high winds or heavy loads. This system is commonly used in tall or complex scaffolding setups.

Q: How does scaffold tie back differ from formwork back propping?

A: Scaffold tie back secures scaffolding to a stable structure, while formwork back propping supports vertical concrete formwork during curing. Both enhance stability but serve different phases of construction. Tie backs focus on lateral support, whereas back propping handles vertical load distribution.

Q: What are key safety guidelines for installing tie back scaffolds?

A: Ensure tie back anchors are attached to load-bearing structural elements. Follow manufacturer specifications for spacing and load capacity. Regularly inspect connections for wear, corrosion, or loosening during use.

Q: When should formwork back propping be implemented?

A: Formwork back propping is used after concrete pouring to support formwork until the concrete reaches required strength. It prevents premature formwork removal that could cause structural defects. Typically applied in slab and beam construction projects.

Q: Can scaffold tie back systems be reused across multiple projects?

A: Yes, if components show no damage or deformation. Inspect all ties, anchors, and connectors for integrity before reuse. Compatibility with new scaffold designs and load requirements must be verified each time.

-

The Essential Role of Timber and Steel in Modern ConstructionNewsMar.10,2025

-

Sustainable Choices in Modern Construction: Steel vs TimberNewsMar.10,2025

-

Key Steel Reinforcement Accessories for Stronger Concrete StructuresNewsMar.10,2025

-

Essential Scaffolding Components for a Safe and Efficient Construction SiteNewsMar.10,2025

-

Comprehensive Guide to Scaffolding ComponentsNewsMar.10,2025

-

Affordable Scaffolding Solutions for Every Construction ProjectNewsMar.10,2025

-

Versatile Scaffolding Solutions for Modern ConstructionNewsMar.03,2025